Call: 07315122499

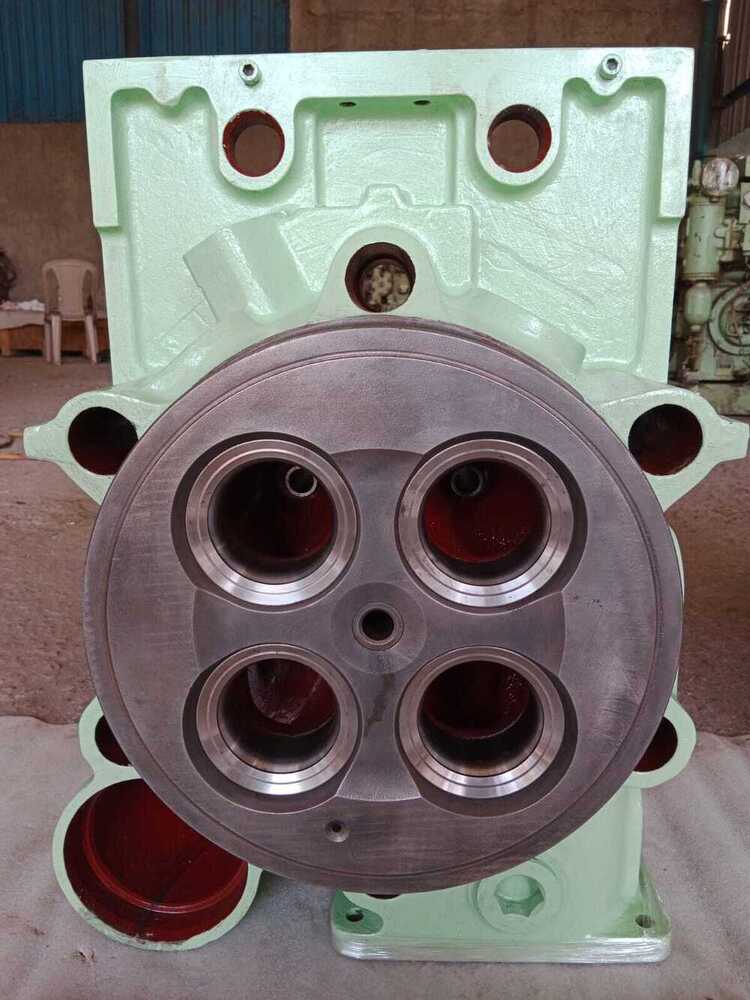

Marine Pump

Price 100000 INR/ Unit

MOQ : 1 Unit

Marine Pump Specification

- Product Type

- Marine Pump

- Type

- Marine Pump

- Automatic Grade

- Manual

- Drive Type

- Manual

- Warranty

- Yes

- Size

- Standard

Marine Pump Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash in Advance (CID), Telegraphic Transfer (T/T)

- Supply Ability

- 1 Unit Per Day

- Delivery Time

- 1 Days

- Packaging Details

- Plastic Wrapping

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Africa

- Main Domestic Market

- All India

About Marine Pump

Marine pumps essential for various shipboard systems typically consist of an impeller shaft casing and sealing mechanisms They are broadly categorized as water pumps for seawater fresh water etc and oil pumps for fuel lubrication etc Specific types include centrifugal pumps selfpriming pumps and submersible pumps each with distinct designs and operating principles

Key Components and Their Functions

Impeller The rotating component that increases the liquids velocity and pressure

Shaft Transmits power from the motor to the impeller

CasingVolute Encloses the impeller and converts kinetic energy into pressure

Sealing Prevents leakage of liquid around the shaft

Bearings Support the rotating shaft

Suction and Discharge Nozzles Connect the pump to the systems piping for inlet and outlet flow

Types of Marine Pumps

Centrifugal Pumps

Commonly used for general marine duties these pumps use an impeller to move the liquid

SelfPriming Pumps

Can draw liquid into the pump without manual priming useful for bilge and wastewater applications

Submersible Pumps

Designed to operate fully submerged often used for cargo transfer or ballast systems

Specific Applications

Marine pumps are crucial for various shipboard systems including

Main Engine Cooling Circulating cooling water for the main engine

Fuel and Lubrication Systems Transferring and circulating fuel and lubricating oil

Firefighting Highpressure pumps for fire suppression systems

Ballast and Bilge Pumping water for stability and removing unwanted water

Freshwater Systems Providing potable water

Sewage and Wastewater Pumping and treating wastewater

Maintenance Considerations

Material Compatibility

Selecting materials resistant to the pumped fluids chemical properties is crucial

Cavitation Prevention

Avoiding running pumps dry to prevent damage from collapsing vapor bubbles

Regular Inspections

Checking for leaks unusual noises and wear is essential for preventing pump failures

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Marine Equipment Category

Marine Parts MAN 28/32 Filter

Price 1000 INR / Unit

Minimum Order Quantity : 1 Unit

Product Type : filter

Warranty : No Warranty

Feature : Low Noise, High Performance, High Efficiency

Capacity : NA Kg

Connecting Rod S6R

Price 100000 INR / Unit

Minimum Order Quantity : 1 Unit

Product Type : Connecting Rod

Warranty : Yes

Feature : ECO Friendly

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry